AIRWUS

Autonomous Intra-Row Weed Removal System

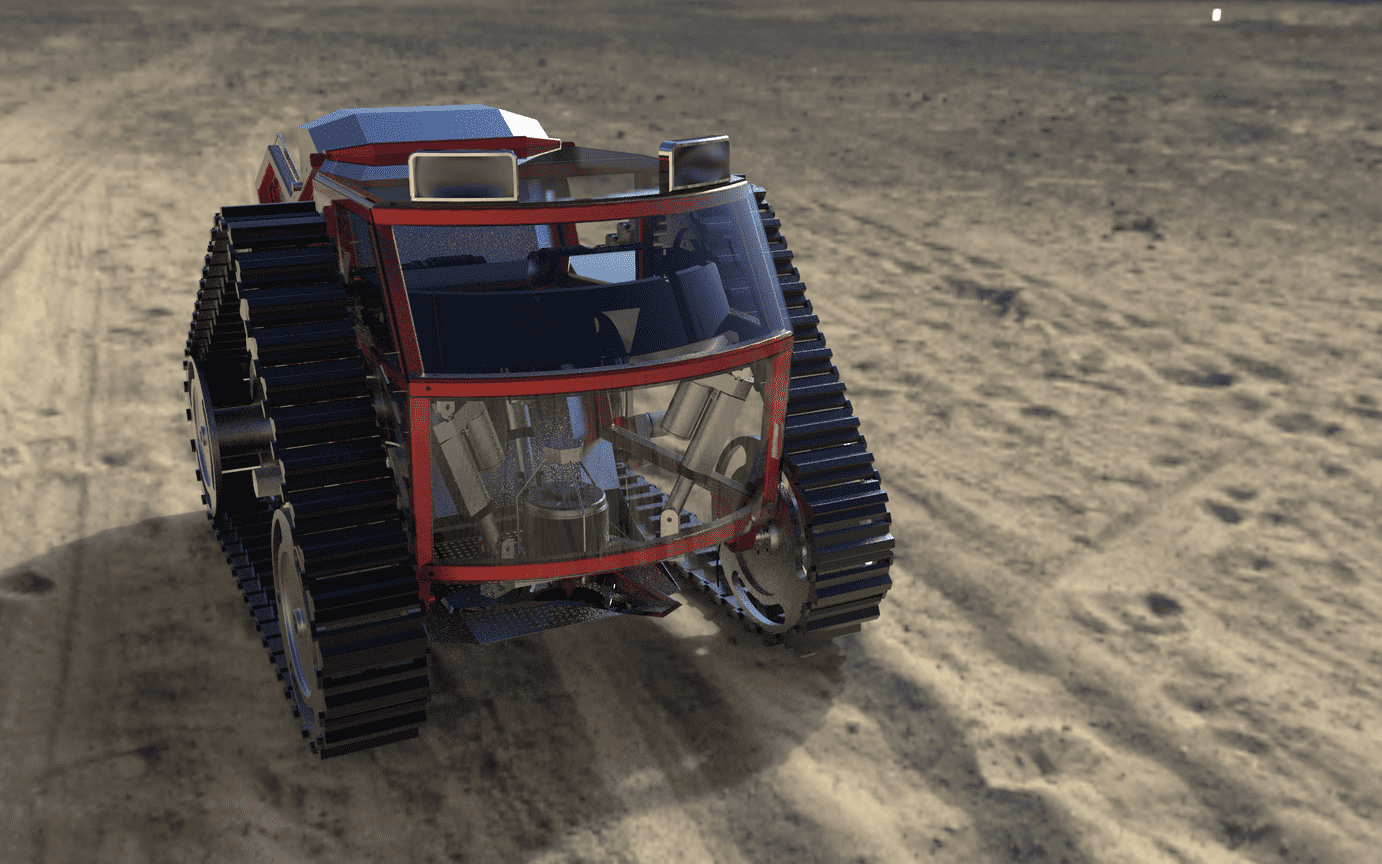

In this project I and Nishchay Sachdeva designed a low-cost Autonomous Weed Removal system for selected Indian agricultural fields. I developed a virtual CAD model, adhering to standard industrial DFM guidelines. Drafted a costing, simulation, analysis & design calculation report with a detailed manufacturing Manual.

Participated (team of 2) in Dassault Systemes product design contest and ended-up Top 10 finalist out of 1120 Participants. Further selected for design presentation at Solidworks World 2019 Conference, Dallas, TX

Work presented at 4th International Conference on Advances in Robotics (AIR), 2019 and published in ACM ICPS Proceedings.

Problem Statement

Availability of unskilled labor, willing to work in the agricultural industry is decreasing day by-day. Nevertheless, demand for laborers in agriculture remains, as it was earlier. As a result, farmers must pay more for laborers. However, there are systems or machines been developed in India which perform a few of the agricultural tasks (harvester, thresher etc.), but many activities still require human interaction or are not automated. Weed (unwanted crops) cutting is one of the tasks done by laborers by hand pulling or by weed removal tool operated by the laborer. Automating the process of weed removal and collection in the agricultural sector will be beneficial for farmer directly or indirectly in a long term manner.

Objective

A systematic design of an Autonomous weed removal system is being provided as a solution to the problem addressed. The objective of the proposed design is to cut weeds of size greater than 3 feet mechanically and collect the same with it, equipped with some additional features that will help farmers in optimizing the process. The design aims to eliminate the need of unskilled labor for the task of weed removal, and perform the task autonomously. The long-term intent of the project is to overcome the challenges faced by the existing solutions for weed removal and also to promote automation in the agricultural sector in an economically feasible manner for the farmers of India.

Detailed Manufacturing Manual

The Manufacturing Manual includes BOM, Raw materials, System tree house & manufacturing details required to manufacture the system

View Manufacturing ManualDesign Calculations, Simulation & Sustainability Report

The Report contains FEA analysis results, cost break-down of the system in INR, Sustainability report for environmental impact (Calculated using CML impact assessment method. & various design calculations of the system.

View ReportSoldidworks World Conference 2019

Participated (team of 2) in Dassault Systemes product design contest and ended-up Top 10 finalist out of 1120 Participants. We were also selected for design presentation at Solidworks World 2019 Conference, Dallas, TX

Author: Mihir Patel